Flexible ducting is considered to be more beneficial than rigid ducting, cost-effective, and ideal for a wide range of HVAC equipment across residential, commercial, and industrial settings. Quickly becoming one of the most popular materials, there are a variety of benefits of choosing flexible ducting over traditional rigid ducting.

Within this article, Searose Environmental will guide you through the differences between flexible ducting vs. rigid ducting, outlining the many benefits that come with using flex duct.

What is flexible ducting?

Flexible ducting is a specific type of air duct that is made from flexible materials. These flexible materials include PVC, polyurethane, and metal-reinforced plastic. Flexible ducting is often used in HVAC (heating, ventilation, and air conditioning) systems to create a connection between different machinery parts. The flexibility of flex ducting is what attributes so many of the well-loved benefits across engineering, construction, and commercial production.

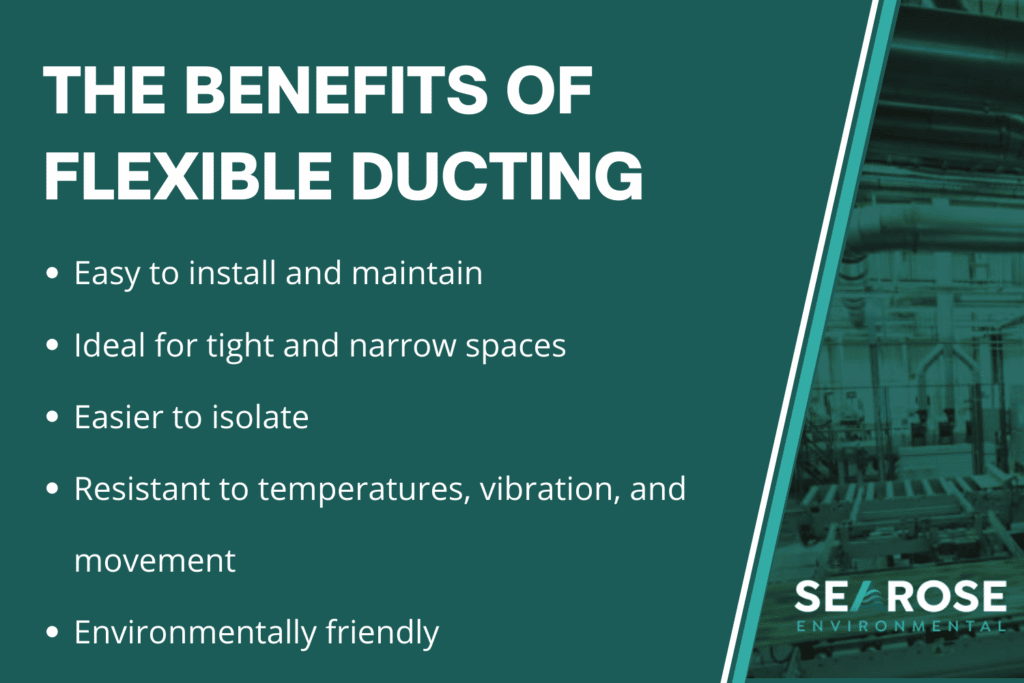

1. Easy installation

Flexible ducting offers numerous advantages that come down to its flexibility; first and foremost, flex ducting is very easy to install, and can be used in narrow and hard-to-reach spaces. Unlike rigid ducting, flexible ducting can be routed around obstacles, and is lightweight, which means it is much easier to attach overhead.

2. Easier to hide

The flexibility of flex ducting also adds to the general aesthetic of a traditional HVAC system which is so often an eyesore. Flexible ducting is easier to hide behind walls, underground, behind columns, and above or within the ceiling.

3. Simple to maintain & replace

As flexible ducting is easier to work with during installation, it’s also easy to handle it during maintenance. Flexible ducting can often be patched or quickly replaced.

4. Thermal insulation

Not only is flexible ducting often more cost effective to purchase, but flexible ducting can also offer savings in the form of thermal insulation. You can reduce energy costs with flexible ducting, as it prevents warm or cold air from escaping, ensuring your HVAC is operating at its most efficient and effective.

5. Noise absorption

Another benefit of flexible ducting is that the materials will absorb noise, vibration, and movement.

6. Environmentally friendly

Lastly, flexible ducting offers an environmentally friendly construction material. PVC, polyurethane, and metal-reinforced plastic are recyclable and resistant to rust, where other ducting materials aren’t.

Flexible ducting vs. rigid ducting

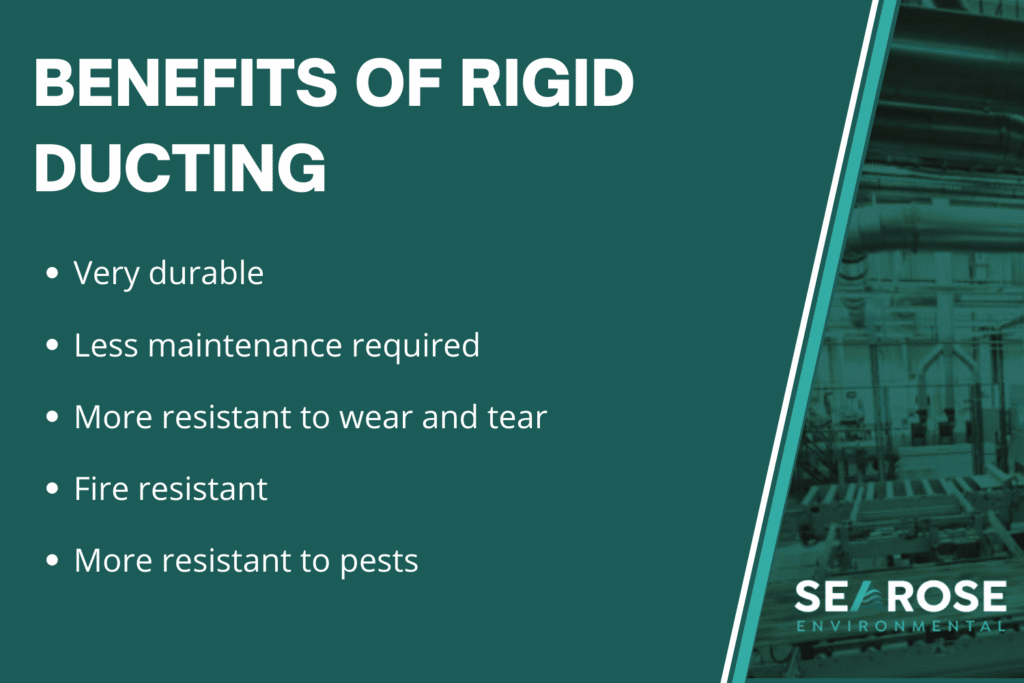

The traditional type of ducting commonly found in both residential and commercial settings is rigid ducting. Made from solid materials like metal or fiberglass, rigid ducting is held together by screws, clamps, or tape. There are a number of key differences between rigid and flexible ducting.

Rigid ducting is not necessarily the best choice for budget-conscious consumers. Rigid ducting is not only more expensive than flex ducting due to the metallic materials, but it also proves more time consuming to work with. Across all types of installation, rigid ducting requires more time and skill, especially when routed behind walls, around obstacles, or in narrow spaces.

Another big difference between flexible ducting and rigid ducting is required maintenance. Flexible ducting is more forgiving if installed incorrectly, as it can be manoeuvred easily, which means that it is also easier to keep clean, move, and maintain. Rigid ducting is not as forgiving, and can be difficult to maintain. However, as rigid ductwork is very durable, repairs are less likely required if installed correctly.

Depending on the material used, rigid ducting can improve the energy efficiency of your HVAC system. However, if installed correctly, flexible ducting can also provide effective thermal regulation.

Flexible ducting also offers resistances against vibration, movement, high and low temperatures, and noise. Rigid ducting, on the other hand, offers more resistance to wear and tear. The stronger and stiffer materials, like fiberglass and metal, are more durable and won’t be pierced as easily as thinner, flexible materials. Furthermore, rigid ducting is more commonly used across commercial properties as it is more fire resistant than flexible ducting that is made from thinner plastic.

Flexible ducting vs. rigid ducting: which should I choose?

When you’re choosing between flexible ducting and rigid ducting, there are a lot of key factors to consider. Firstly, it is important to assess the area in which the ducting will be installed. When it comes to narrow and hard-to-reach spaces, flexible ducting is the better choice. It can be easily hidden behind walls and rerouted around objects, which is ideal for a lot of commercial and residential spaces. If it is to be installed an area that is easy to access and you’re not worried about aesthetics, the long-lasting rigid ducting may be the better option.

Secondly, consider the costs involved. Flexible ducting is less expensive than rigid ducting in both material and installation costs. If budget is a factor in your decision-making process, flex ducting is probably the better way to go. However, if you’re looking to make a long-term investment into an effective and long-lasting HVAC system, (for example, in a commercial building), rigid ducting is a good choice. The installation may be more expensive but pays for itself through fewer repairs.

Lastly, consider the ducting’s usage. It’s important to think about how the materials are going to be used, and where they are going to be used. Consider noise pollution, efficiency, and

For more information about flexible and rigid ducting installation, services, or products, or speak to the experts at Searose Environmental today on 1300 484 849 or reach out to us online.