Environment management is a critical part of industrial workplace safety. Compliance with strict workplace safety measures often require adequate dust collection and clearing systems, of which there are two main solutions: dust collectors and vacuum systems.

Dust collectors and vacuum systems both collect and remove debris in industrial environments, but their applications lie in vastly different areas. Understanding the key differences in their function and industrial application is essential for plant managers and operators looking to ensure the safety of their workspaces.

We’re going to compare the two solutions – but let’s first start with the basics:

What is a Dust Collector?

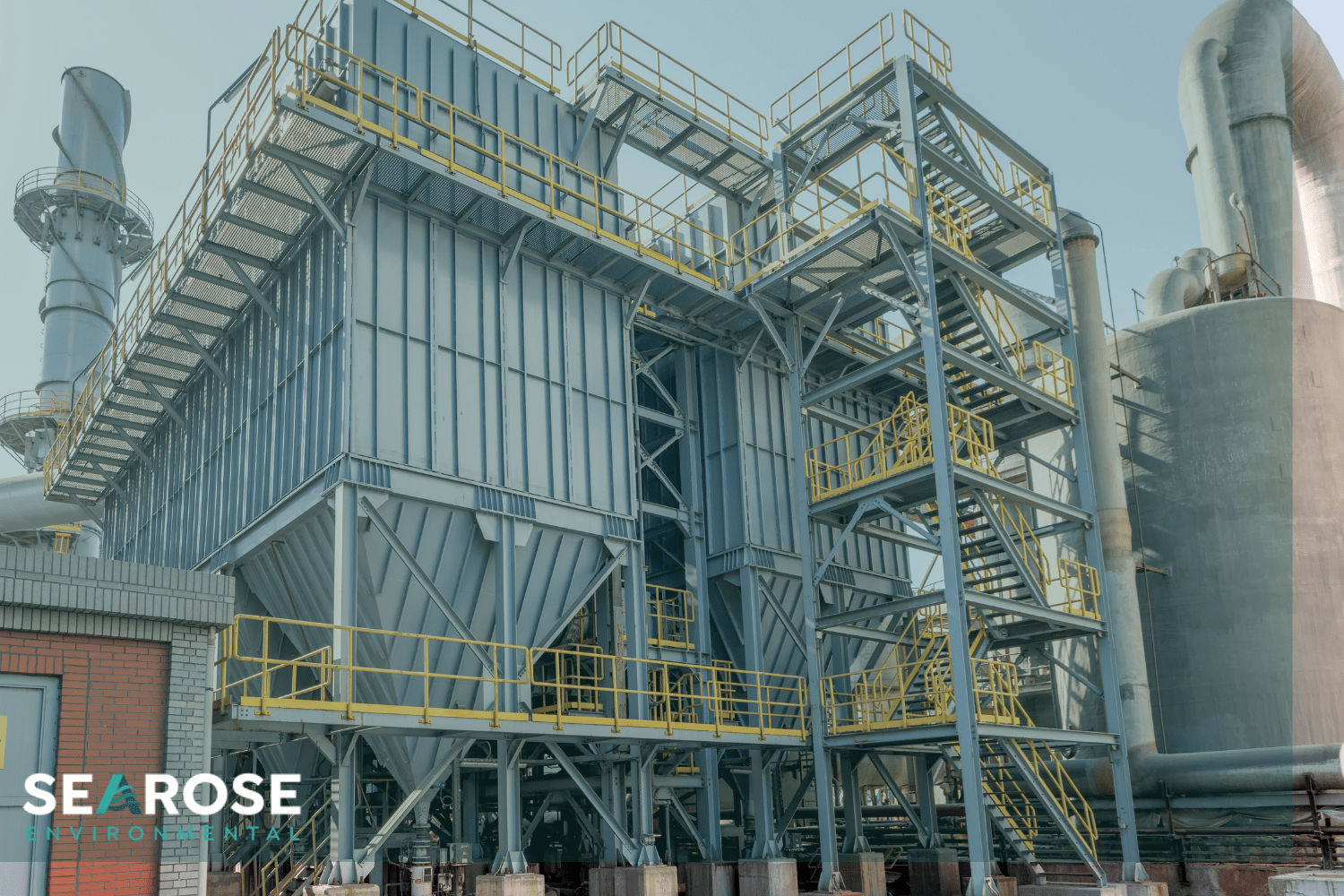

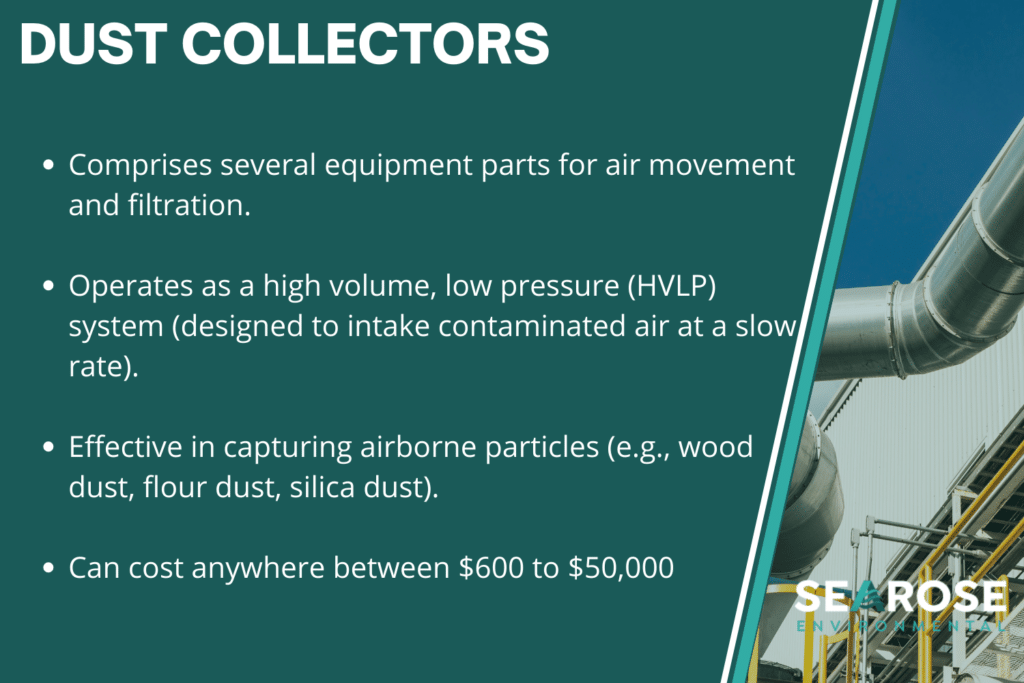

Dust collectors consist of a number of equipment parts that work together for the purpose of moving and filtering air. Dust collector hoods serve as the main intake point for air and are connected by ducting pipes to a filtering system and exhaust port. The configuration for dust collectors usually differs between worksites based on the specific needs of the environment.

The key thing to note about dust collectors is that they are high volume, low pressure (HVLP) systems. This simple means that they are designed to take in a lot of contaminated air at a slow rate. Airborne particles such as wood dust, flour dust, and silica dust that linger in the environment are easily picked up by dust collection systems and removed from the air.

Dust collectors are best used in environments where these harmful airborne particles are often generated, including the following types of industrial work:

- Wood working

- Chemical processing

- Metal or rock cutting

- Crop processing

- Pharmaceutical manufacturing

What is a Vacuum System?

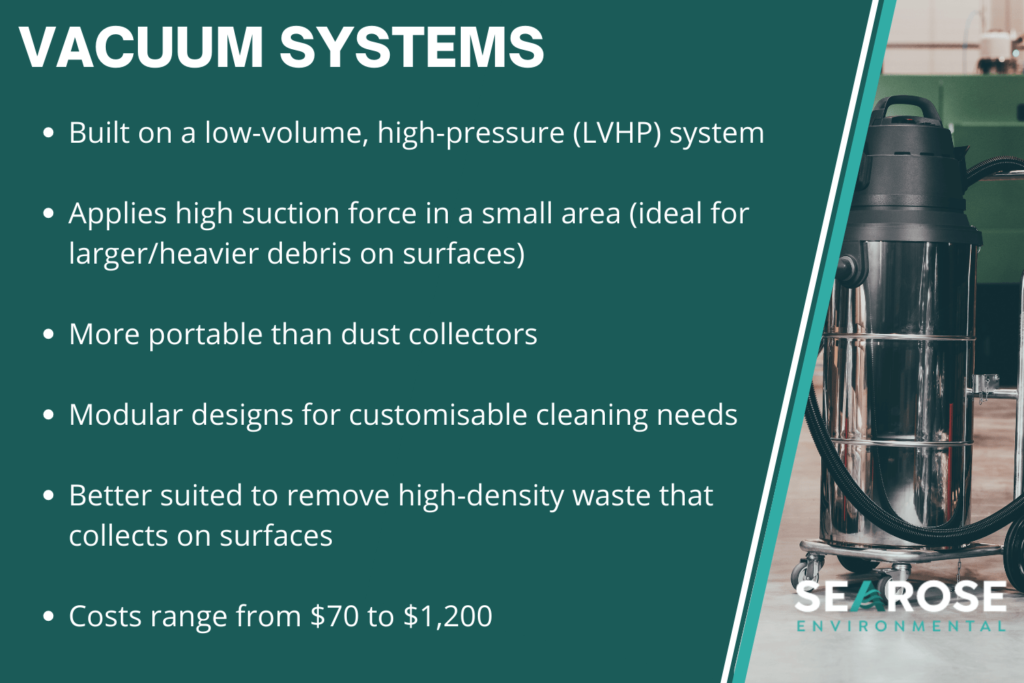

Vacuum systems for industrial applications are built on the same working principle as commercially sold vacuum cleaners for the home or vehicles — low volume, high pressure (LVHP). Notice that this is directly opposed to how dust collectors work.

Because of their ability to apply high amounts of suction force in a small area, vacuum systems are best used for larger or heavier debris in the worksite that collects on the ground or other surfaces, such as wood shavings or loose seeds.

Vacuum systems are also notable more portable than dust collection systems due to their limited reach. Most vacuums come fitted with a brush or narrow intake head that is joined to a flexible hose that leads into a collection chamber where debris is trapped.

More often than not, vacuum models also come with modular designs that allow parts to be swapped out to suit difference cleaning requirements. These can include longer hoses to increase collection distance and dusting brushes to sweep debris out of hard-to-reach areas.

Industrial vacuum systems are ideal for managing the following types of workspace debris:

- Scrap metal

- Paint powder

- Wood chips

- Non-toxic liquid spills

- Food particles

Key Differences Between Dust Collector and Vacuum System

Type of Collection

As we’ve covered earlier, dust collectors and vacuum systems are better suited to specific types of debris and dust removal. HVLP dust collectors should be used to remove waste particles lingering in the air, helping to keep the workplace air free from contaminants. LVHP vacuum systems are better suited to remove high density waste that collects on surfaces.

Portability

Dust collection systems can only filter out air in localised areas where their hoods are installed, meaning that proper placement is a major factor in determining their effectiveness. Vacuum systems can usually be wheeled around to target high mess or waste generation areas around the worksite, making them more suitable flexible applications.

Cost Comparison Between Vacuum System and Dust Collector

Aside from safety, having the appropriate type of equipment for the type of dust management needed can greatly enhance operational efficiency, resulting in cost savings. The cost of dust collectors are usually much higher than vacuum systems due to the complexity of their installation and integration with the building’s ventilation system.

Dust collection systems can cost anywhere between $600 to $50,000, depending on the number of parts and how extensive the system needs to be.

In contrast, vacuum systems only cost from $70 to $1,200 based on the capacity and power of the model.

Considering that dust collectors have the more comprehensive role of ensuring that the quality of air in the entire workspace remains safe to breathe, it becomes easier to justify their higher costs as an investment for the worksite. To add to that, dust collectors are needed throughout an entire day of operation compared to vacuum system units, which may only see use at certain intervals.

Choosing Between a Dust Collector and Vacuum

As a plant safety manager or operator, it is your responsibility to ensure a safe working environment for your staff. The choice of purchasing dust collectors or vacuum systems should not be mutually exclusive one. If your industrial operations produce dust particles that may potentially contaminate the air, a dust collection system will be required — but that should not stop you from also considering vacuum systems to clean up larger piles of debris.

At Searose Environmental, we specialise offering dust collection solutions in Brisbane for all types of industrial businesses and operations. We cover dust collection system installations, maintenance, and repair. If you have a worksite that needs professional dust control, contact us today for a free no obligation quote from our expert team.