An industrial dust collector is an excellent investment in your company, and the overall air quality of your operations. With the right dust extraction system, you are protecting your employees, products, and machinery. However, without the right maintenance, industrial dust collector repairs can quickly become expensive. The trick to ensuring that your dust collector continues operating seamlessly all year-round, is to take care of the equipment through maintenance.

Below we’ve put together a guide on industrial dust collector maintenance. By following these five tips, you can ensure effective and durable equipment.

But first, let’s look take a look at where dust collectors are most commonly used.

What Is an Industrial Dust Collector?

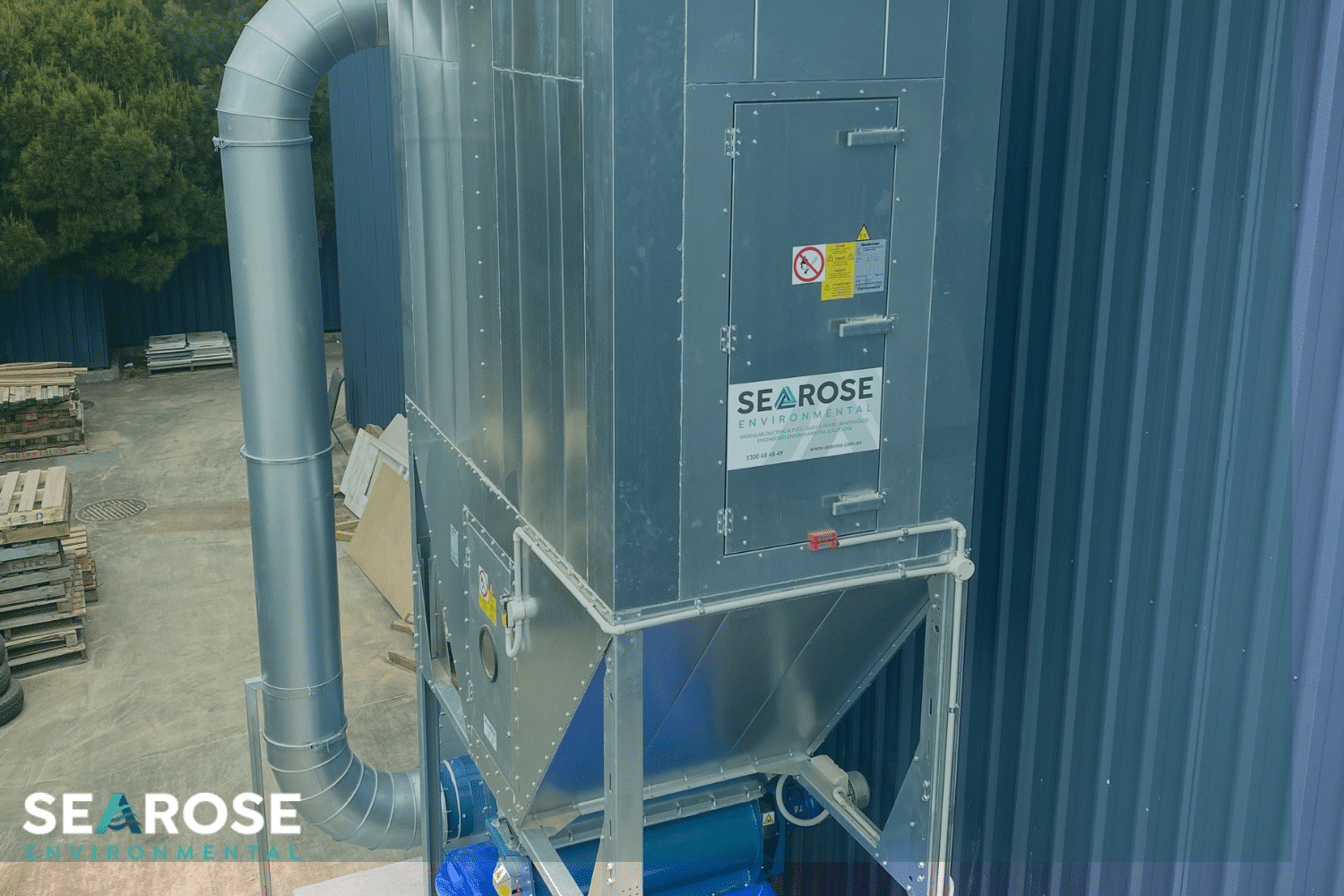

An Industrial dust collector (or dust collection system) is an air filtration system specifically designed to remove particles from indoor or closed off space. An adequately installed industrial dust collector removes dust and other contaminants from the industrial environment. Therefore, dust extractors are vital for specific industries to create safe and healthy workplaces without air pollution.

Here are the most common areas that rely on dust extraction equipment:

- Woodworking

- Manufacturing

- Painting

- Mining

- Chemicals

- Pharmaceuticals

- Food Processing

- Power Plants

- Textile

- Construction

Five Tips for Industrial Dust Collector Maintenance

After successfully installing an industrial dust collector, maintenance is vital to ensure the equipment is operating as effectively and efficiently as possible. To make sure dust collection equipment continues to operate seamlessly, here are five actionable tips to maintain the durability and integrity of an industrial dust collector:

1. Regular Inspections

Like anything, maintenance starts with cleaning and regular inspections. The more often you get your equipment cleaned and inspected, the more likely you’re going to come across any potential issues early on, that can be remedied without any major repairs.

Over time, dust and other particles from your workplace can build up in the system, decreasing the overall the efficacy of the equipment. Whether you use a dust collection system for the entire manufacturing plant, or for a segmented area, regular inspection and professional cleans are vital to promote a healthy, clean working environment.

2. Use the Right Filtration System

The right filtration system is crucial for an effective dust collection system. Depending on the environment, different filtration systems will be required for different air pollutants. While a woodworking site will need to get rid of the pollutants that come from sawdust in the air, chemical plants must filter fine particles and chemical fumes. Therefore, depending on each site’s requirements, different filters are required – this will ensure that your system is operating seamlessly for as long as possible.

3. Fan & Motor Maintenance

The fan and motor are the lungs and heart of your industrial dust collector. Regular maintenance of these two parts should be part of each site’s routine to ensure long lifespan.

Regular lubrication with the manufacturer’s recommended instructions is vital. Furthermore, regular checks for wear and tear helps to spot leaks and cracks in the fan and motor area of the dust collection system. Always replace worn parts as quickly as possible to reduce bigger problems down the line!

4. Lubricate Bearings

Aside from the motor and blower, the bearings need regular lubrication to ensure smooth operation and prolong longevity. As different dust collection systems may require specific lubricants, always stick to the recommendations of the manufacturer. Moreover, it is essential to clean the bearings before lubricating. So, remove any dirt or debris that could cause problems before applying the right lubricant.

5. Monitor for Any Unusual Sounds

As an industrial dust collector will often be used over a variety of workplaces and areas on-site, it is crucial to keep a close eye on performance. Unusual sounds, such as rattling and clanging, can indicate potential damage or sediment build up in the system. If you notice anything untoward, it’s best to get an inspection and service booked in.

The Benefits of Using an Industrial Dust Collector

Using an industrial dust collector has many benefits for the work environment. From improved air quality to reduced maintenance costs, here are five benefits of installing an industrial dust collector:

Air Quality: First and foremost, installation of an industrial dust collector will improve the air quality of the work site. With the right equipment, dust, particles, and other pollutants will get filtered out of the air – creating a healthier, safer workplace.

Efficiency: Removing the dust and pollutants from a workplace will increase overall industrial efficiency and efficacy. Dust collection equipment will protect sensitive machinery from unwanted particles, which can pose a quality risk for industries like food processing and pharmaceuticals.

Maintenance Costs: As mentioned, particles and pollutants in the air can cause damage or inefficiencies to industrial machinery. Dust collection will extend the life of important equipment by filtering pollutants out of the air, reducing the rate at which your machinery will wear down or need to be serviced – reducing overall maintenance costs.

Productivity: Better air quality can improve the productivity and well-being of your employees.

Compliance: Some industries, like mining or wood processing, have strict regulations when it comes to air quality. Installing a high-quality industrial dust collector will ensure your site fulfils all compliance regulations.

Wrapping Up

A high quality, durable industrial dust collector is an important investment for many industries. However, equipment will only be as good as you keep it – regular maintenance is the key to ensuring durable, efficient, and effective dust extraction. If you need someone who knows the ins and outs of industrial dust collectors, Searose Environmental is Queensland and Sydney’s leading dust collector repair and maintenance experts. We design, install, repair, service, and maintain all forms of dust extraction machinery – and are always focused on increasing the system’s efficiency and durability. Get your equipment serviced by getting in touch with Searose Environmental online today or by calling 1300 48 48 49.