Wondering “How do camlock fittings work?”, and “How to measure camlock fittings?”. You’re not alone. Searose Environmental have put a comprehensive guide to cover the ins and outs of camlocks fittings, from how they work, to how to measure them, and finally, installation of the fittings in various scenarios.

What Is a Camlock Fitting?

Camlock fittings, also known as cam and groove couplings, connect two hoses or pipes for transfer or delivery of a material. The fittings are used as end connections on suction hoses, discharge hoses, and other low-pressure flexible materials delivering fluids – although they can also be used for dry goods. So, how do camlock fittings work?

How Do Camlock Fittings Work?

A camlock fitting works by using a two-part connection known as a male/female coupling system. This coupling system provides a threadless, easy-to-use system that enables quick and reliable seals to transport materials and commodities. Due to their effectiveness, they are used across the world and in almost every industry.

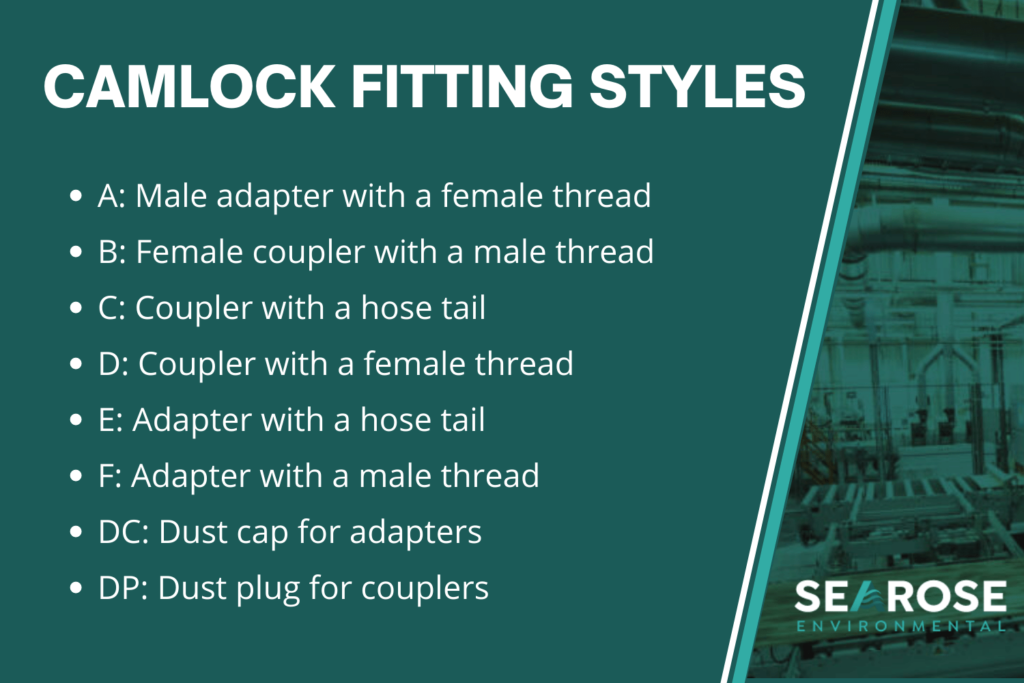

While serving the same primary purpose, there are eight different styles of camlock fittings, each with slightly different connections. They are identified by letter and are as follows:

Each style caters towards specific industry needs and is more ideally suited to certain materials, diameters, or applications.

What Materials Are Camlock Fittings Made From?

As each style of fitting provides a slightly different connection tailored to various scenarios, you may be confused about the intricacies of how do camlock fittings work in terms of the materials they are made from.

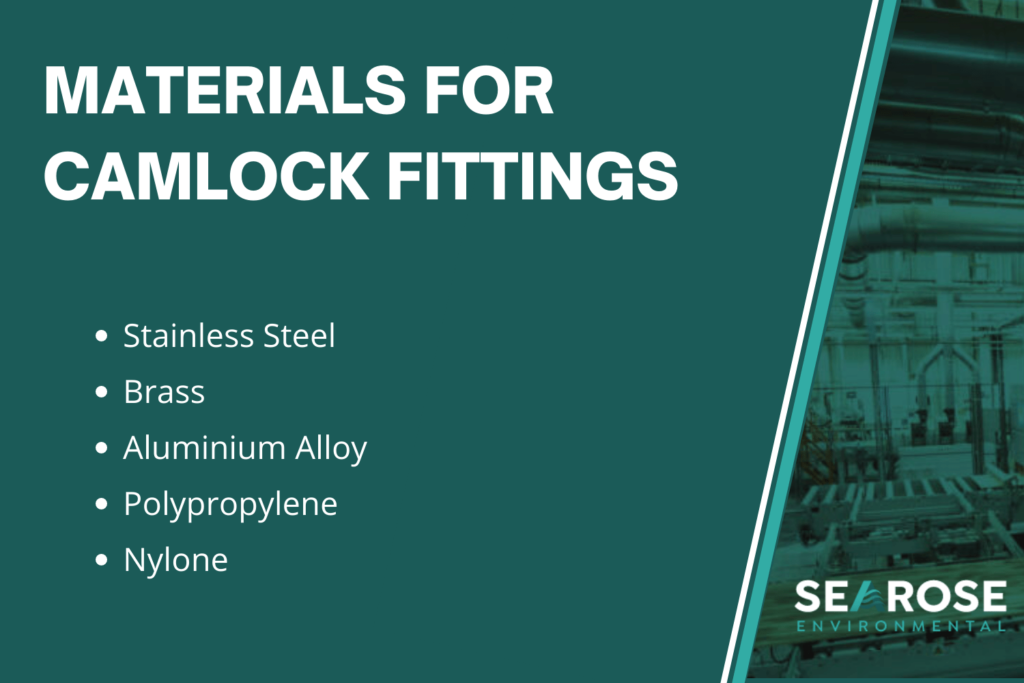

Camlock fittings are made from several materials, including:

Stainless Steel, known for its strength and durability, to ensure performance for various substances and applications. Stainless steel can withstand high temperatures and is resistant to corrosion from liquid or chemicals.

Brass fittings offer similar thermal performance and resistance to corrosion as stainless steel. Still, brass fittings are the preferred choice in marine applications as they perform better with water, coolant, gasoline, hydraulic oils, and petroleum.

Aluminium Alloy fittings provide a lightweight and cost-effective alternative to the more expensive fittings. Like brass, aluminium alloys are commonly used for water, hydraulic oil and petroleum-based products.

Of the non-metal materials, there is Polypropylene and Nylon. Although not as strong as metal fittings, polypropylene camlocks are durable, handle harsh chemicals, and provide a cost-effective alternative. They are most used in agricultural and industrial applications. Nylon fittings offer relatively the same performance as polypropylene but can handle higher temperatures and cope with changing humidity levels.

What Is a Camlock Fitting Used For?

As one of the most popular types of couplings in the world, Camlock fittings are used for a whole host of applications. To give you a better idea of how does a camlock work, we have included some examples of real-world applications:

Oil Distribution: Many organisations worldwide use camlocks as a standardised connector to deliver petrol to service stations and homes. You may have even seen these fittings yourself when filling up or looking at a petrol tanker truck.

Military: Aluminium, anodized fittings are approved for use by NATO forces worldwide for agile tactical deployment.

Agriculture: As they come in acid-resistant materials, camlock fittings work well as hose connectors for irrigation and spraying.

Paints, Inks, and Dyes: As they can tolerate multiple coatings without any damage occurring around the seals, camlock fittings are used in the manufacturing process of paints inks and dyes, which frequently change pipes and hoses when developing mixtures and colour formulas.

Cleaning: Camlock fittings are used in cleaning, especially industrial cleaning as the fittings provide a quick and effective solution that is preferred over storing and transporting hoses.

What Are the Benefits of Camlock Fittings?

Now that we have a better idea of how camlock fittings work, let’s look at the many benefits the fittings can provide. The various materials and styles that complement the primary function of camlock fittings offer a whole host of benefits that everyone can take advantage of. Knowing these benefits can also inform your decision when deciding if camlock fittings are the right solution you’ve been looking for.

Durability: Camlock fittings come in various materials, so users can choose the type that will work best for their specific project or use.

Quick: Due to their design, camlock fittings provide fast connection and disconnection between hose and pipes while maintaining a secure seal for the transfer or delivery of a commodity.

Easy to Use: The beauty of camlock fittings is that they achieve a reliable seal without the need for any tools. All that is required is fitting the male and female ends together and pulling back on the handles.

Versatile: Camlock fittings are applicable in almost any industry that requires the transportation of liquids, powders, or gases. They come in various sizes and specifications to meet a variety of needs.

Now that we know of the benefits, let’s look at how to measure camlock fittings and ensure you are choosing the right size and model for your application.

How Do You Size a Camlock Fitting?

The most common method of measuring camlock fittings is to measure the outside diameter of the adapter head or the inside adapter of the coupler. If you were to measure the outer diameter on a metallic camlock adapter, the associated coupler would be known by the same internal measurement. For instance, a 2-inch adapter would fit with a 2-inch coupler. However, as polypropylene fittings do not have an international standard and manufacturers use different head sizes, you must ensure you choose the dimensions that fit together. For instance, a ½ inch hose tail fits a ¾ inch body.

How to Measure Camlock Fittings:

The best way to obtain a precise measurement and ensure you choose the right components is to use electric callipers. They are measuring instruments that provide readings to a high degree of accuracy and are especially useful when measuring components’ internal and external diameters.

How Do You Install Camlock Fittings?

So, we have covered how to size camlock fittings and how to measure camlock fittings, now it’s time to look at installation. The beauty of camlock fitting is that the installation process is very straight forward.

The answer to “how do you install camlock fittings?” is simple if you have correctly measured and sized your components.

To attach the two sections, you must have a male groover adapter on one section and a female couple on the other. To connect the two, you must first extend the handles on the coupler outwards and slide the male adapter into the female coupler. Once inserted, you close the handles on the coupler simultaneously, so the coupler and adapter are pressed together.

The rationale for closing the handles at the same time is to ensure the adapter is pulled evenly into the seal and no gaps or leaks can occur during the transfer of the commodity. This is especially true during the transfer of liquids.

To disconnect the camlock fitting, all you need to do is open both the handles and pull the male adapter out of the coupler. Before disconnection, it is essential that the hose assembly has been depressurised.

Choosing a Camlock Fitting

It is not only important to know how does a camlock work, but also how to choose the right camlock fitting for your specific purpose. A common acronym used to guide the selection process for a Camlock fitting is S.T.A.M.P.E.D.

It is vital to consider the above factors to choose the correct fitting for you. If you chose the wrong size, you might be unable to install your camlock fitting on the desired hose or pipe. If you choose the wrong pressure rating or material type, you might break your fitting and lose the transferred material. When you choose the right style and consider the S.T.A.M.P.E.D factors, you can enjoy the leakproof full flow transfer of various materials that Camlock fittings provide.

If you are unsure which fitting is suitable for you, it would be best to speak to an expert technician who has a thorough knowledge of the various types of fittings and experience in installing and using them.

Experts in Industrial Fittings and Engineering

If you would like to know more about how do camlock fittings work and their industrial and commercial applications, do not hesitate to contact the team at Searose Environmental.

At Searose Environmental, we are specialists in environmental engineering solutions in both commercial and industrial settings. Our pneumatic conveying and industrial equipment maintenance solutions are among our services that support our customers and the transport of their materials.

We also have a wide range of products and equipment such as flexible ducting and hoses that directly interface with camlock fittings.

To learn more about our service offerings and product range, call our team today or submit an enquiry through our contact page.