Perhaps you’ve upgraded your workshop with larger, more powerful equipment, or you’ve just begun your journey into the wonderful world of woodworking. You might be asking, “just how big of a dust collector do I need?”

Inhaling dust of any kind can be the cause of harmful respiratory illness. As such, it is crucial to ensure you understand how to size a dust collector so as to safeguard the health and safety of yourself, those around you and any other machinery in the environment.

Fortunately, your dust collector’s necessary size can be determined through just a few simple calculations that will tell you the required flow capacity, how much static pressure loss can be overcome, and how big the ductwork needs to be.

As Queensland’s leading providers of dust collectors, Searose Environmental endeavours to ensure the safety of your working environment. Our team of specialists provide professional design, supply, installation and dust collector servicing solutions to suit any and all of your dust extraction and dust control needs.

What Is a Dust Collector?

A dust collector is used to improve air quality in industrial, commercial, workshop and factory areas by collecting dust and other air impurities. Moreover, dust collectors also capture wood shavings and chips on top of the dust particles you can’t see.

A dust collector system consists of many parts and filters, as well as reverse pulse cleaning, shaker motors, electronic controls, subduct lines, flexible hoses, pressure transducers, a centrifugal fan, reverse blow fans, rotary valves and control dampers.

How Does a Dust Collector Work?

So just how does a dust collector work? Dust collectors are intentionally designed to purify and filter hazardous particles released within a working environment.

Dust collectors work by vacuuming up dust particles from the air before moving them through the system’s ductwork into a collection area. From here, the dirty air is pushed through a filter that splits the substances before exuding purified air back into the airspace.

How Big of a Dust Collector Do I Need?

It cannot be understated just how important it is to have an adequately sized dust collector within the workspace. A dust collector that is too small will fail to effectively capture harmful substances, exposing you and your colleagues to potential health risks. A dust extraction system that is too big will take away space that could be otherwise used for more equipment, incite unnecessary running costs or damage your ductwork.

When asking how big of a dust collector you should install, your attention should turn to calculating what the maximum airflow through the system will be. You can deduce this by listing all the tools that will connect to the dust collecting system. A CFM calculation should accompany each device.

CFM stands for ‘cubic feet per minute’ and refers to how much airflow each part requires for the effective disposal of dust particles. CFM is the essential aspect to consider in understanding “how big of a dust collector do I need?” as your dust extraction system must be able to cope with the required CFM.

How to Calculate CFM

The answer to the question “how big of a dust collector do I need?” lies within CFM. Once the maximum CFM is discovered, we know how big the dust control equipment must be to adequately protect those in the environment. There are several different ways we can calculate CFM:

1. Research Typical Airflow Values Online

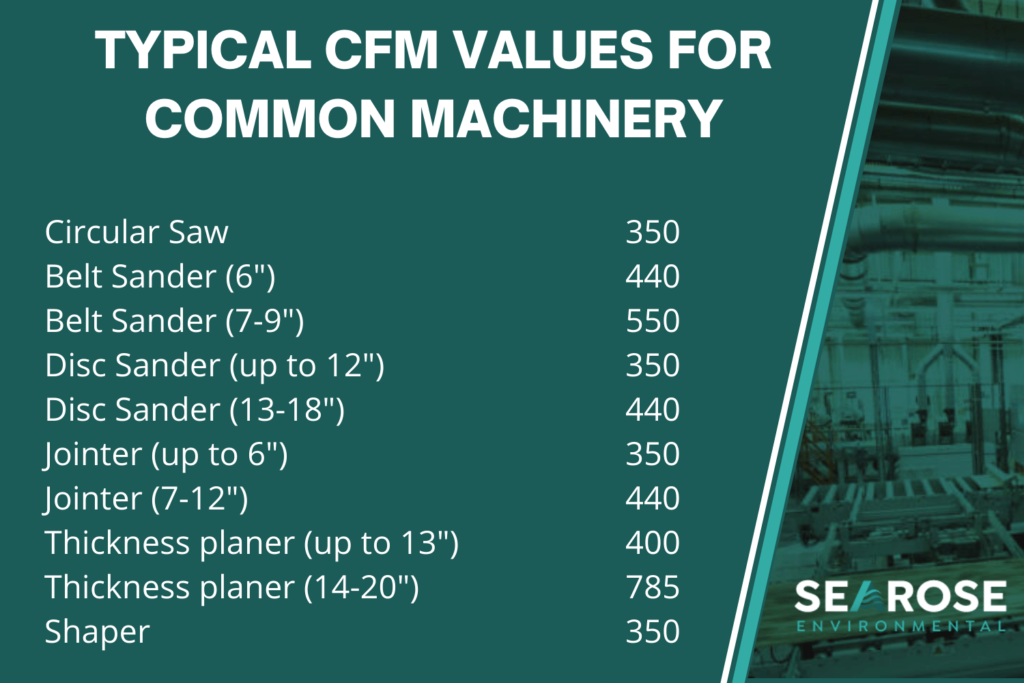

Most machines used in industrial spaces and workshops will have a standard accompanying CFM value that you can research online. However, the individual parts within your workshop may vary from this estimation, perhaps due to size, make or type. This method should be used more as a guide rather than a definitive value.

2. Look It Up in the Instructional Manual That Comes with Your Tools

Check the manual that comes with your respective tool, as the manufacturer may have accurately calculated the CFM already. You can then spend the time that calculations would otherwise take on using the machinery itself!

3. Manual Calculation

Calculating the CFM needed for your dust collector does not require mathematic expertise, but it will take a number of calculations. Following this guide, you should have no more doubts about how to size a dust collector for your workshop.

Firstly, you must measure flow velocity. Flow velocity is determined with the following equation:

V = 4005 x √ΔP (square root of velocity pressure)

Note: velocity pressure can be measured by a pressure sensor.

Example: V = 4005 x √0.75 = 0.866

4005 x 0.866 = 3,468.

Flow velocity = 3,468 ft/min.

Secondly, you must determine the cross-sectional duct area. If the duct is rectangular, simply times the duct width by duct height in feet.

If the duct is circular, you must measure the diameter. Convert the diameter into feet before halving this value for the radius. Proceeding this, you must multiply the radius squared by pie (3.14).

Example: An 18” diameter round duct. 18” diameter = 1.5ft2. Therefore, the radius = 0.75

A = π x r²

r2 = 0.752 = 0.5265

A = π x 0.5625 = 1.77ft2

Finally, you must determine the airflow in CFM by multiplying your two measurements together.

Airflow in CFM = Flow velocity in feet per minute (FVPM) x Duct cross-sectional area (A)

Example: 3,468 ft/min x 1.77ft2 = 6,128 CFM.

Therefore, your CFM would be 6,128 using this example.

Note: The most significant CFM number out of all your tools will be the minimum benchmark for what is required in size for your dust collector.

The final step in your calculation requires you to determine the static pressure loss within the system’s ductwork. Static pressure is representative of the friction between the air moving within your ductwork and the surrounding walls. In order to make the air move toward purification, the blower must be able to overcome the friction inside. The more angles and indents inside your ductwork, the greater the loss of static pressure.

To calculate, first consider each branch separately. Measure the length of that branch duct in feet. Add up the branches as well as your central duct to calculate your total static pressure loss. Make sure that every piece of ductwork inside your dust collector is considered. Now that you know how to size a dust collector, you can begin to search for a dust collector that exceeds these measurements.

Searose – The Experts in Dust Control

Have you calculated your maximum CFM flow and figured out how big of a dust collector that you need? Have you cleared out some space in your workshop? Now it’s time to select the right dust collector for you. At Searose Environmental, we custom design dust collection systems that are unmatched in performance and reliability. Shop our full range of dust collectors today or enquire with our team on 1300 48 48 49. Searose Environmental can also provide leading dust control Brisbane installation and dust collector maintenance services that are sure to keep your focus on the work at hand.